UVLack Technology: Future of Eco-Friendly Industrial Coatings

Across America’s manufacturing and design industries, innovation is driven by one key factor — efficiency without compromise. Companies want finishes that are fast, flawless, and environmentally safe. That’s where UVLack comes in a UV-cured lacquer technology reshaping how products are finished and protected.

Unlike conventional coatings that rely on heat or air to dry, UVLack harnesses ultraviolet light to cure instantly. The result is a finish that’s smooth, durable, scratch-resistant, and visually striking — all while being safer for the environment. Whether you’re a furniture manufacturer in North Carolina, a packaging printer in California, or a design firm in New York, UVLack coatings bring a high-performance edge to your work.

In this comprehensive guide, we’ll explore what UVLack is, how it works, its benefits, applications across industries, and why it’s gaining massive traction in the U.S.

Table of contents

- What Is UVLack?

- How UVLack Coating Works

- Advantages of Using UVLack

- Key Applications of UVLack

- The UVLack Process Explained

- The Rise of UVLack in the U.S. Market

- UVLack vs Traditional Finishes

- Trends and Innovations in UVLack Technology

- Maintenance and Care for UVLack Surfaces

- Industry Use Cases in the United States

- Sustainability and Green Manufacturing

- Challenges in Adopting UVLack

- Common Myths About UVLack

- The Future of UVLack in America

- Conclusion

- FAQs

What Is UVLack?

The term UVLack stems from “UV lacquer,” a coating cured by ultraviolet light instead of natural evaporation. This technology uses a blend of acrylic resins, monomers, and photoinitiators — chemicals that react under UV exposure to trigger polymerization. Once exposed to UV light, these components crosslink, turning a liquid layer into a solid, protective film in seconds.

This rapid-curing process eliminates long drying times and reduces production energy consumption, making it ideal for industrial settings that require both speed and precision.

Common Uses of UVLack in the U.S.

- Furniture and Wood Panels: High-gloss or matte protective finishes for cabinets, tables, and decorative boards.

- Automotive Components: Interior panels, dashboards, and trims benefit from the scratch resistance of UVLack.

- Printed Materials: From book covers to luxury packaging, spot UV coatings emphasize logos and text.

- Electronics and Appliances: Smooth, resilient coatings for device casings and display surfaces.

- Flooring and Countertops: Protects against daily wear and maintains a lasting sheen.

Essentially, UVLack provides the visual perfection and longevity modern consumers expect in a fraction of the time.

How UVLack Coating Works

The science behind UVLack is simple yet ingenious. Traditional coatings dry when solvents evaporate, leaving a solid film. UVLack, however, relies on photopolymerization a reaction that occurs when UV light activates photoinitiators in the coating. These photoinitiators trigger molecular crosslinking, solidifying the coating almost instantly.

This process happens in milliseconds, depending on the intensity of the UV lamp and the thickness of the coating.

Why UV Curing Matters

- Speed: Immediate curing means faster production cycles.

- Precision: The coating doesn’t flow or sag, producing an even finish.

- Sustainability: No need for solvent evaporation, drastically reducing emissions.

- Durability: The polymerized film is dense and strong, offering long-term protection.

For U.S. manufacturers aiming to improve output without compromising quality, UVLack is a clear step forward.

Advantages of Using UVLack

1. Instant Curing for Maximum Efficiency

Traditional coatings can take hours to dry, slowing down production lines. UVLack cures in seconds under UV light, allowing immediate handling, stacking, or packaging.

2. Superior Surface Quality

UVLack delivers unmatched clarity and smoothness, ideal for achieving mirror-like gloss or velvety matte textures.

3. Eco-Friendly Manufacturing

With minimal or zero volatile organic compounds (VOCs), UVLack complies with U.S. EPA environmental standards, supporting green manufacturing initiatives.

4. Exceptional Resistance

UVLack coatings resist scratches, chemicals, and yellowing crucial for furniture, flooring, and automotive interiors that endure daily wear.

5. Long-Term Cost Benefits

While UV curing systems require upfront investment, the long-term savings in energy, materials, and labor make them a smart financial choice.

Key Applications of UVLack

UVLack coatings serve diverse industries in the United States. Below are the most common applications:

- Wood Furniture and Cabinetry: Enhances natural grain while protecting against moisture and stains.

- Luxury Packaging: Creates high-contrast spot UV effects that elevate brand perception.

- Commercial Printing: Used in business cards, catalogs, and magazines for tactile and visual appeal.

- Automotive Manufacturing: Adds resilience and shine to dashboards and trims.

- Electronics Manufacturing: Safeguards device surfaces against scratches and fingerprints.

- Architectural Panels: Protects decorative wall panels and doors from abrasion.

- Musical Instruments: Adds gloss and protection to guitars, pianos, and wood finishes.

These applications underline UVLack’s versatility — from industrial manufacturing to high-end creative projects.

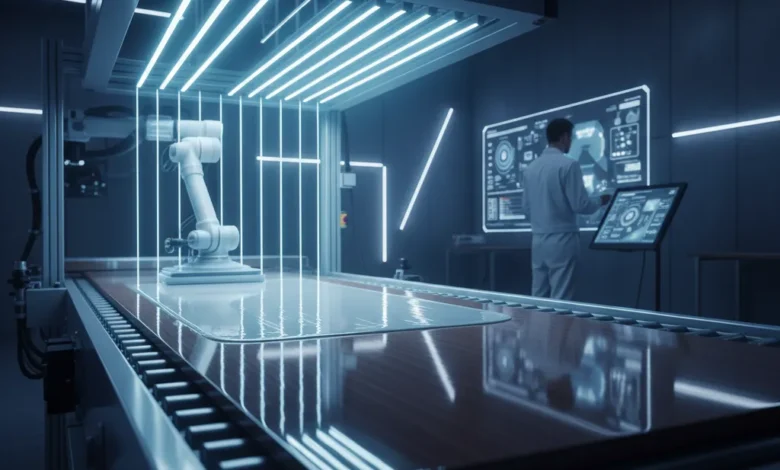

The UVLack Process Explained

Surface Preparation

A clean, smooth surface ensures proper adhesion. Dust, oils, or residue can disrupt the curing process.

Application

UVLack is applied using techniques such as spraying, roller coating, or curtain coating, depending on the product type.

UV Exposure

The coated object passes through a UV curing line equipped with high-intensity lamps. Within seconds, the liquid coating solidifies into a hard, durable film.

Cooling and Inspection

After curing, the item cools and undergoes quality checks for uniform gloss, texture, and defect-free surfaces.

This streamlined process reduces downtime, energy waste, and production costs — all while delivering consistent results.

The Rise of UVLack in the U.S. Market

Over the past decade, UVLack coatings have surged in popularity across American industries. This growth stems from evolving consumer expectations, sustainability goals, and stricter regulations on solvent emissions.

Environmental Regulations Driving Adoption

The U.S. Environmental Protection Agency (EPA) and various state-level agencies — particularly in California — have implemented strict limits on VOC emissions. Manufacturers seeking compliance have turned to UVLack as a safer, low-emission alternative.

Demand for Premium Aesthetics

From Apple’s glossy product finishes to luxury packaging for cosmetics, the U.S. market associates visual quality with brand value. UVLack provides that premium look consumers expect.

Competitive Production

With American companies under pressure to shorten lead times and reduce costs, UV curing allows faster turnaround without sacrificing finish quality.

UVLack vs Traditional Finishes

| Feature | UVLack Coating | Traditional Coating |

|---|---|---|

| Curing Time | Seconds under UV light | Hours or days |

| VOC Emissions | Minimal or none | High |

| Durability | High scratch and chemical resistance | Moderate |

| Energy Consumption | Low | High (due to heating) |

| Finish Quality | Glossy or matte precision | Variable |

| Production Efficiency | Excellent | Average |

The clear winner for modern American manufacturing is UVLack balancing performance, sustainability, and aesthetics.

Trends and Innovations in UVLack Technology

The U.S. coatings industry is seeing rapid innovation in UVLack formulations and curing systems.

1. LED-Based UV Curing

Traditional mercury UV lamps are being replaced with LED systems that consume less energy and last longer. They also generate less heat, allowing coating on heat-sensitive materials like plastics or paper.

2. Hybrid UV Coatings

Manufacturers are developing hybrid UV coatings that combine waterborne and UV-curable technologies for even lower VOCs and greater flexibility.

3. Smart Functional Coatings

Some advanced UVLack coatings now include antimicrobial properties or self-healing capabilities — ideal for healthcare and electronics sectors.

4. Custom Finishes

U.S. designers are experimenting with tactile UV finishes soft-touch matte, brushed texture, or holographic effects to create distinct sensory experiences.

Maintenance and Care for UVLack Surfaces

Maintaining UVLack-coated surfaces is straightforward. The cured layer’s density prevents stains and makes cleaning easy.

- Use soft, non-abrasive cloths for wiping.

- Avoid harsh solvents; mild soap and water suffice.

- For furniture, periodic polishing can refresh gloss.

- Protect surfaces from extreme temperature fluctuations for longevity.

With minimal upkeep, surfaces can retain their original appearance for many years one reason American homeowners and businesses favor them.

Industry Use Cases in the United States

Furniture Manufacturing

American furniture makers, especially in North Carolina and Ohio, utilize for premium cabinetry, office desks, and kitchen panels. It reduces drying time from hours to seconds, enabling faster order fulfillment.

Printing and Packaging

In the printing industry, UVLack revolutionized how brands highlight their identity. Spot UV techniques — where UVLack is selectively applied create contrast, depth, and tactile appeal on business cards, brochures, and product packaging.

Automotive and Aerospace

The durability of UVLack coatings suits interior automotive components exposed to sunlight and friction. Its resistance to fading and scratches ensures lasting quality.

Flooring and Architectural Panels

U.S. flooring manufacturers favor for its abrasion resistance and easy maintenance, perfect for high-traffic commercial spaces.

These applications demonstrate how UVLack bridges functional protection with visual excellence.

Sustainability and Green Manufacturing

One of UVLack’s greatest appeals to U.S. industries is its alignment with sustainability goals. The push for greener production isn’t just regulatory it’s a competitive advantage.

Lower Carbon Footprint

UVLack’s instant curing minimizes energy use compared to conventional heat-drying ovens.

Zero or Low VOCs

Since UVLack formulas are often 100% solids, they release almost no harmful emissions during application.

Material Longevity

A longer-lasting coating reduces the need for refinishing, conserving resources over time.

This makes coatings not only good for business but also better for the planet.

Comparing UVLack to Traditional Coatings

Traditional solvent-based coatings require hours or even days to dry completely. They also release VOCs, contributing to air pollution.

In contrast, UVLack cures in seconds, emits little to no VOCs, and provides a harder, more resilient finish. It’s a win-win for both manufacturers and the environment.

Another major advantage is precision control can be applied in selective “spot” areas (known as spot UV) to create contrast and highlight design elements, a popular technique in packaging and print media.

Challenges in Adopting UVLack

While UVLack offers numerous advantages, its adoption requires careful planning.

- Initial Investment: UV curing systems (lamps, conveyors) can be costly upfront.

- Material Compatibility: Some substrates may need primers for optimal adhesion.

- Process Expertise: Operators must understand UV lamp intensity, exposure time, and coating thickness for perfect results.

Despite these challenges, the long-term benefits lower operational costs, faster throughput, and superior finishes far outweigh the learning curve.

Common Myths About UVLack

Many people mistakenly believe UVLack coatings are only for high-end or luxury projects. In truth, they are scalable for all types of production from small craft businesses to large-scale industrial operations.

Another misconception is that UVLack is difficult to apply. With modern UV curing systems, the process is straightforward, cost-effective, and accessible even for mid-sized manufacturers.

The Future of UVLack in America

As American consumers demand higher quality and sustainability, UVLack is set to dominate the coatings market. Industry forecasts predict consistent growth in UV-cured finishes, particularly in furniture, electronics, and packaging sectors.

Advancements in LED curing, bio-based resins, and smart coatings will continue to expand its applications. Companies adopting UVLack today are positioning themselves at the forefront of modern, responsible production.

Related insight: Prizmatem – The Future of Layered Design and Thinking

Conclusion

From glossy magazine covers to resilient furniture finishes, UVLack represents the future of coating technology in the United States. Its combination of speed, strength, and sustainability makes it indispensable for industries seeking efficient and eco-friendly finishing solutions.

More than just a coating, UVLack is a statement a commitment to quality, innovation, and environmental responsibility. As manufacturers and designers look to meet evolving consumer demands, this UV-cured lacquer stands out as a shining example of how technology and artistry can coexist beautifully.

FAQs

Q1. What is UV lacquer used for?

UV lacquer is used to create durable, glossy, and protective coatings on surfaces such as wood, metal, plastic, and paper. It’s common in furniture, packaging, and automotive industries.

Q2. Is UV coating durable?

Yes. UV coatings offer superior hardness and resistance to wear, scratches, and chemicals. They also retain their finish longer than traditional coatings.

Q3. What is the difference between UV coating and varnish?

UV coating cures instantly under ultraviolet light, while varnish dries slowly through solvent evaporation. UV coatings are also more eco-friendly and resilient.

Q4. Can UVLack be used on all materials?

It works best on smooth, non-porous surfaces like wood panels, PVC, and coated paper. Proper surface preparation ensures optimal adhesion.

Q5. Is UVLack environmentally friendly?

Absolutely. Most coatings have minimal VOCs and lower energy requirements, making them an eco-conscious choice for U.S. manufacturers.